CAUSTIC SODA FLAKES AND LIQUID MADE IN TURKEY AND UAE

- Home

- CAUSTIC SODA FLAKES AND LIQUID MADE IN TURKEY AND UAE

We are Caustic soda exporter from Turkey and UAE (Dubai) to global market

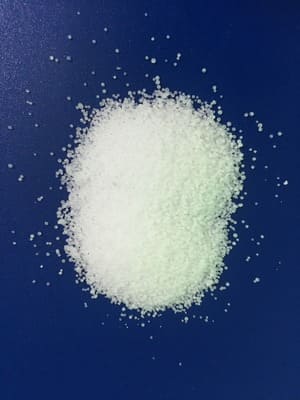

Basekim Caustic soda flakes is an important chemical with wide applications in many industries which known as some other names like sodium hydroxide, lye, caustic and etc in different markets and with have various purities and types in two different shapes liquid and solid is supplying by BASEKIM company to all over the world.

What is caustic soda?

Base kim caustic soda is a highly hydroxide substance that is use to neutralize acids and make sodium salts. Sodium hydroxide physically is a white crystalline like snow, odorless and solid that absorbs moisture from the air. It is easily soluble in water when dissolve or neutralized with acid it liberates substantial heat, which may be sufficient to ignite combustible materials. Sodium hydroxide is very corrosive.

It is generally using as a solid or a 50% solution. Other common names include caustic soda flakes and lye. More than 95% production capacity of chlorine and approximately 100% of the production capacity of cadmium (sodium hydroxide) is based on the hydrolysis of salt water. In this process, a solution of sodium chloride (salt water) is decomposed electrically to elemental chlorine and a solution of sodium hydroxide and elemental hydrogen. a liquid production method using sodium chloride as a raw material is a multiprocessing process today, there are generally three commonly use methods to produce it.

Table of Contents

ToggleCaustic soda PH

At a concentration of 1 mol/L, the pH of caustic soda solution is approximately 14, which represents a highly alkaline solution. As the concentration decreases, the pH of the solution decreases as well, moving towards neutrality (pH 7). Dilute solutions of caustic soda may have a pH in the range of 11-13, depending on the concentration.

Caustic soda for sales and usage sectors

- Acid neutralization

- Manufacturing of soaps and detergents

- Pulp and paper industry

- Oil and gas industry

- Pharmaceutical industry

- Aluminum processing

So far Caustic soda in many fields has noticeable usages somehow that the range of it applications is from foodstuffs to chemical making.

Lye also is use for aluminum industries, pulping, sewage refinery, rubber bleaching and detergents, water purifying, making tiles, pharmaceutical, ceramics, artificial silks, color making, leather and textiles, cosmetics, glass making, gas and oil industry, batteries, neutralize acids, soft drinks, alcohol making, sugar making, oil industries, polymers, stick industries, disinfectants and lots of other industries which need it is producing by Basekim company and exporting to all over the world.

Where to buy caustic soda

The best quality of caustic soda is from UAE (Dubai) ,China and Indian factories, Iran and Turkey.

Reference of business and inspection report

Usage of caustic for the paper pulping

Paper pulping ,there are wide range of chemicals which use in paper industry in another way its tell paper chemicals .Chemical usage is not only for imparting properties to paper but to handle the water cycles in the process, conditioning of fabrics, cleaning of equipment and several other applications.

Why use caustic soda in paper pulping?

Preparing the pulp involves separating out the cellulose fibers from the plant material. Many plant materials are very tough and require boiling in sodium carbonate (soda ash) or caustic soda (lye) at ph 12-14 to accomplish.

It is a key component of the white liquor solution use to separate lignin from cellulose fibers in the sulfate process. It is adding to increase the ph in the pulping process of fibers. The higher ph of the paper-fiber solution causes the fibers to smoothen and swell, which is important for the grinding process of the fibers.

Caustic soda in Kraft pulping

It is also use in Kraft pulping process involves treatment of wood chips with a hot mixture of water, caustic soda , and sodium sulfide (Na2S), known as white liquor.

This product in the Kraft process or Sodium Hydroxide in soda pulping are use to break the lignin bonds of wood being process into pulp for papermaking. Using recycle chemicals as makeup from other sources (spent caustics) aids in the reduction of the environmental impact of chemical pulping.

Why caustic soda use in detergents?

Detergent , Caustic soda is often use to manufacture cleaning products like soaps and detergents. The chemical formula for detergent is: C 18 H 29 NaO 3 S.

It is perfect for removing stains from clothing, upholstery, leather, carpeting and linens on your bed and in the bathroom. It quickly removes grease, paint, ink, blood, coffee and other food stains on your clothes.

Caustic soda use for soap

It is the most commonly-use alkali, but if it is too expensive or not available, caustic potash can be used. Caustic soda produces a hard soap, whereas caustic potash makes a softer soap which is more soluble in water. In soap and detergent industry, it is using in saponification, the chemical process that converts vegetable oils into soap. It is using to manufacture anionic surfactants, a crucial component in most detergent and cleaning products.

Main chemical in detergent

The most important are sodium silicate (water glass), sodium carbonate (soda ash), sodium perborate, and various phosphates.

Chemical name and common name is washing soda, lime stone, soda lime, baking soda. It is an alkali and has several uses. As the name suggests washing soda is commonly use in detergents.

What does caustic detergent clean?

Furthermore caustic cleaners, use for clean Bacteria, fungi, yeasts, viruses, and endotoxins . Caustic cleaners are use worldwide within detergent

Using caustic soda in washing machine detergent

This includes defoamers, surfactants, and rust inhibitors. A parts washer heats detergent and water in a close cabinet, spraying them at pressure against dirty parts for degreasing applications. While parts washer detergents base on sodium hydroxide are among the most aggressive parts washer cleaning chemicals, they are also consider environmental improvements over the solvent-based cleaning methods.

Packing of Caustic soda and shipment

Since it has water attraction and the humidity causes to reduce the quality of this matter, need to has safe and moisture proof packing and according to this our company has the modern packing machines with ability to support various volume of the customer requests in multiple layer packing’s with strong standards and with different capacities for different markets and also with printing the privet logo on the bags as an option. The provided caustic soda by Basekim with the highest quality, safe packing, affordable price and strongest standards is ready to transfer to any spot on the world.

Jumbo Bags

This bag model is only for easy handling of cargo sent by moving or transporting machines. In this type of packaging, 25 kg caustic soda bags are place in a larger package that can hold up to 40 bags. And this bag is suitable for preventing sunlight, air and moisture.

25 Kg Bags

This type of bag has a width of 50 × 80 and is the best possible packaging for caustic soda, especially for export abroad. Corrosion and decay of the yarn along the way, which in turn causes the lid of the bag to open and the lump inside to clog due to contact with air or moisture.

Pallets

This packaging model has been created only for easy transportation. In this model, some 25 kg bags of caustic soda are place on a durable plastic or wooden pallet, and using different materials such as plastic next to each other hold them tight.

Planting industry and caustic soda

Planting industry and caustic soda , or in other words its chemical name, sodium hydroxide, is known as a corrosive substance that works especially well on organic materials such as soil, food, and hair. This substance can be dissolve in water, which is one of the reasons it works so well on close drains, and also NaOH is usually use to adjust the pH of the medium and to prepare the storage solution of growth regulators in plant tissue culture.

Application of caustic soda in neutralization of acidic soil

At planting industry caustic soda is uses to neutralize acidic environments, which explains its frequent use in the production of chemicals. Because sodium hydroxide is a very strong base, it is often use to absorb acidic secretions or gases that can be neutralized with a base. Caustic potash is usually a white solid that can dissolve in less than its own weight in water. It has universal applications in soaps and detergents, fertilizers and industrial operations.

Is caustic soda harmful to plants?

The caustic soda can kill many invasive trees when apply directly to a cut stump. and also 96% of all pesticides are produce using chlorine.

Effects of caustic soda for planting industry

Sodium hydroxide (NaOH), also call caustic soda or lemon, is a corrosive white crystalline solid that contains the cation Na + (sodium) and the anion OH – (hydroxide). It easily absorbs moisture until it dissolves.

The low salt index and high solubility of potassium hydroxide make it ideal for mixing liquid fertilizers. Potassium strengthens the root system of plants, which enhances disease resistance in plants, increases yield and overall quality of crops, prevents wilting and improves drought tolerance of crops.

Scientists can use sodium hydroxide to absorb carbon dioxide from the air so that plants do not use it in photosynthesis.

Sodium hydroxide is use to remove the skin of tomatoes, potatoes, and other fruits and vegetables for canning, and is also use as an ingredient in food preservatives to help prevent the growth of fungi and bacteria in food.

How is caustic soda use in water treatment industry?

water treatment industry to raise the pH of water mainly use caustic soda. it does this by absorbing water and carbon dioxide, and is commonly an integral component of water treatment.

It is a white, alkaline, flakes and odorless pack in drums.Sodium hydroxide, or NaOH is a commonly use water treatment chemical that raises the pH of water by absorbing water and carbon dioxide, and also hydrochloric acid, hydrated lime, sulfuric acid, are chemicals that help make contaminants in wastewater stick together, so they will be easier to remove, the optimum dosage to reach the recommend pH of 12 is around 26 g of soda per litter of faecal sludge. The exact amount, however, de pends on the characteristics of blackwater or sludge. Its effect can be enhanced by ensuring complete mixing, a longer contact time and a higher dosage of caustic soda. The pH should be maintained above pH 12 for a minimum of 2 hours to ensure an adequate reduction of pathogens.

Description of Caustic soda water treatment industry process

The Caustic Soda Treatment process should be undertaken as a batch process and can be used to treat both solid and liquid sludge. After treatment, pH decreases towards neutral usually within 24 hours. After neutralization, the supernatant can be pumped off and safely infiltrate into a Soak Pit . Care should be taken in areas with high a groundwater table as the supernatant still contains ni trogon and phosphorous which can pollute water bodies. The treated solid fraction at the bottom may be applied as a soil amendment or dried and use as cover for sanitary landfill om water.

What happens when caustic soda reacts with water?

pH value will increase and become much greater than 7 on adding it to water. Caustic soda is general name for NaOH which is a strong base. So, when we add caustic soda to water, it will make the water basic in nature. A basic solution has a pH greater than 7.

The reaction will be Exothermic, where heat will be released. Sodium hydroxide is consider a strong base and as such is able to completely and fully disassociate in aqueous solution.

why use caustic soda in liquid like water?

It is using primarily to increase and control pH in water-base fluids. Is a source of hydroxyl ion to increase and control ph.

What is the ratio of caustic soda to water?

Regular treatment with half strength mix (250g Caustic Soda to 6 litters of water) will prevent further blockages. Cleaning & sanitizing (dustbins, kennels, stables, driveways etc.) Add 1-2 tablespoons of it per 5 litters of water

Effect of Soda Ash and Caustic Soda in Water treatment

This treatment method is use if the water is acidic (low PH). Soda ash (sodium carbonate) and sodium hydroxide raise the pH of the water to near neutral when inject into a water system. Unlike neutralizing filters, they do not cause hardness problems in treated water.

Injection systems are point-of-entry systems. A corrosion-resistant chemical feed pump injects soda ash or sodium hydroxide solution into the water to raise the ph. The solution should be fed directly into the well to protect the good casing and pump from corrosion.

If the water needs to be disinfected as well as neutralize, dual treatment is possible within the injection system by adding a chlorine solution (sodium hypochlorite) along with the neutralizing chemical. Injection systems can treat water with a pH as low as 4.

Industrial Cleaning and Caustic soda

In industrial Cleaning ,Sodium hydroxide is one of the strongest bases, It is both a degreaser and a cleanser. It dissolves grease, oil, and protein-base deposits, producing a water solution that you can wash off.

Surfactants can be added to the sodium hydroxide solution to stabilize the dissolved material, thereby preventing re-deposition. Prevent.

Sodium hydroxide soaking solution is use as a strong degreaser on stainless steel and glass bakeware. It is also a common ingredient in stove cleaners.

In industrial production, it is common to save time by adding a salt such as sodium chloride to the sodium hydroxide solution to combine cleaning and disinfection.

The role of caustic soda in the industrial cleaning process

Sodium hydroxide is often use as an industrial cleaning agent, often refer to as a “beneficial”. It is adding to water, heated, and then use to clean process equipment, storage tanks, etc. It can dissolve fat, oil, grease and protein-base deposits

Which chemicals are use for industrial cleaning?

Simple chemicals are also widely use in the production of industrial cleaners. These include: soda, sodium hypochlorite and hydrochloric acid and Caustic soda.

The benefits of sodium hydroxide as a cleaning agent

Sodium hydroxide is widely accept for cleaning, disinfection and storage of chromatography media and systems and use for resins.

Usage of Caustic soda at cleaning resins

For resins, the most important cleaning agent is sodium hydroxide. Some reports indicate that heated sodium hydroxide is an excellent cleaning agent. Even without heating, high concentrations of sodium hydroxide require evaluation of facilities and equipment and the use of safety equipment to protect workers.

During limit inspections, manufacturers of biopharmaceuticals and biological products typically focus on verifying the cleaning and disinfection of chromatographic resins and multipurpose purification systems. Chromatography resins must either be discarded or cleaned sufficiently to ensure reproducibility in subsequent cycles.

Over the years, various cleaning agents have been proposed. After evaluating a new cleaning agent for a resin, make sure it is also compatible with system components.

The roll of Sodium hydroxide to remove nucleic acids

Nucleic acids can bind strongly to the anion exchangers of chromatography equipment. 1 M sodium hydroxide and 3 M sodium chloride, with a total contact time of one hour, efficiently removed labeled calf thymus DNA from a weak anion exchanger.

Usage of Caustic soda in the process of extracting aluminum

Aluminum , is the largest caustic soda application segment in the chlor-alkali market. Caustic soda is use in the process of extracting alumina from bauxite ore. It dissolves bauxite ore, which is the raw material for it production. In this process, pure alumina is separate from bauxite ore. The collected alumina is further subject to calcination.

How alumina reacts with caustic soda?

Therefore, when alumina , which is an amphoteric metal, reacts with caustic soda, sodium aluminate is formed and hydrogen gas is evolve as a result.

The reaction is as follows:

Aluminum + 2 Na O H Caustic soda + 2H2O → 2Na A lO2 Sodium met aluminite + 3H2 ↑ Hydrogen gas

This reaction is very exothermic.

what is Bayer process for product alumina?

The Bayer process is the principal industrial means of refining bauxite to produce alumina (aluminum oxide) and was developed by Carl Josef Bayer. Bauxite, the most important ore of alumina, contains only 30-60% aluminum oxide (Al203), the rest being a mixture of silica, various iron oxides, and titanium dioxide. The alumina oxide must be further purified before it can be refined into alumina metal. For this process use caustic soda, It dissolves bauxite ore.

The position of caustic soda in the category of chlor-alkali products

Chlor-alkali products include chlorine, caustic soda, and soda ash. The main technologies use in the chlor-alkali process are membrane cell, diaphragm cell and mercury cell to produce chlorine. The chlorine produced from the electrolysis of an aqueous solution of sodium chloride (common salt or Na Cl). Soda ash is producing from the mining and refining of Tron ore (natural) and also through the Solvay process (synthetic). The chlor-alkali process is energy intensive.

Drilling grade Caustic soda in drilling fluids

Drilling fluids ,Caustic Soda provides many solutions to aid in drilling and fractions.

Soda ash is use to raise the pH of make-up water for bentonite and polymer drilling by precipitating soluble calcium.

It helps to solubilize acidic compounds, it assists in reducing the corrosively of water-base drilling , it increases the hydration rate of disperse clays, and in lime-base drilling muds, it is reducing the solubility of lime.

Using caustic soda will increase the performance of bentonite and polymer drilling industry . Soda ash should be added slowly through a hopper or chemical barrel.

Effect of caustic soda on pH?

Soda is using to maintain or increase pH. Increasing pH with sodium hydroxide precipitates magnesium (Mg2+) and suppresses calcium (Ca2+) in high hardness waters such as seawater, reduces corrosion, and neutralizes acid gases such as carbon dioxide (CO2) and hydrogen sulfide (H2S).

Importance of Ph on drilling fluids

Water can have a primary influence on the success of any type of drilling. The efficiency and success of drilling projects can be easily determined by the water use. importance of water in drilling industry is clear , since water makes up 95 to 99 percent of the drilling fluid using. Importantly, the pH of drilling mud is one of the key parameters to determine its performance. As such, it performs better within pH range of 8.0 to 10.5 for water base mud.

Paint remover Caustic soda

Paint remover ,Caustic soda is well known for its properties for stripping paint. It allows to remove the layers of paint or varnish as quickly as possible and with the least fatigue. We can use it as a solvent-base paint stripper. Caustic soda is an excellent stripper for wood and metals. Using soda lye reduces the risk of surface damage that may occur using other methods.

Why is caustic soda use as a paint remover?

Paint remover , typically sodium hydroxide (also known as lye or caustic soda), work by breaking down the chemical bonds of the paint, usually by hydrolysis of the chain bonds of the polymers forming the paint. A solution of sodium hydroxide in water was traditionally use as the most common paint stripper. However, it seems that an effective and cheap alternative to the mechanical removal of paints and coatings from the surface.The most common utilize of paint stripper along with water is Caustic soda and Trisodium phosphate hydrolyze and decompose the paints and that can be removed.

Gold mining grade of Caustic soda

Caustic soda, also known as sodium hydroxide (NaOH), is sometimes use in gold mining to extract gold from ore. The process, known as “cyanide leaching,” involves mixing finely ground ore with a cyanide solution and then adding caustic soda to the solution to raise its pH level. The increase pH level causes the cyanide to dissociate into its ionic form, which can then react with the gold to form a soluble complex that can be separated from the ore.

The use of cyanide leaching with caustic soda is a common method for extracting gold from low-grade ores, as it is relatively inexpensive and efficient. However, it is also a highly toxic process that poses significant environmental risks if not manage properly. The cyanide solution and other chemicals use in the process must be contained and properly dispose of to prevent contamination of water sources and other environmental damage.

In recent years, there has been increasing interest in alternative gold extraction methods that do not rely on cyanide or other toxic chemicals, such as thiosulfate leaching or bioleaching. These methods are still being develop and test, but they offer the potential for a more environmentally sustainable and socially responsible approach to gold mining.

Process of remove paint with 10% aqueous solution of sodium hydroxide

Caustic soda is the most popular preparation to remove paint is. To prepare it, measure the right amount of caustic soda and gradually pour water into it, while stirring the contents in the container vigorously.

How much caustic soda does need to strip paint

For paint stripping need to Add 250g Caustic Soda to 1 litter of cold water. Apply carefully with an old paint brush.

MSDS of caustic soda

Classification

This material is consider hazardous by the OSHA Hazard Communication Standard (29 CFR 1910.1200)

Skin corrosion/irritation Category 1 Sub-category A

Serious eye damage/eye irritation Category 1

Acute aquatic toxicity Category 3

Label Elements

EMERGENCY OVERVIEW

Physical Hazards Corrosive to Metals Category 1

Precautionary Statements – Prevention

Keep only in original container

Do not breathe dusts or mists

Wash face, hands and any expose skin thoroughly after handling

Wear protective gloves/protective clothing/eye protection/face protection

Avoid release to the environment

HS code of custom tariff of soda flakes

HS code of caustic soda is 2815

Caustic soda price on 2023

Caustic soda prices are depends on many items which we are dealing everyday and normally its update base on each week. from the 2022 which Russia and Ukraine war start prices in European market face with inflation because the energy imports mainly from Russia and by sanction against Russia many factories face with energy issues so for a few month prices goes up .

Caustic soda price in Asia effect by region china play key role covid 19 makes some limitation in production and transportation also in col weather government force factories in china to shut down their factory to be able control the weather pollution .

Weekly caustic soda price

Caustic soda flakes 550 USD/MT EXwork

Caustic soda flakes 590 USD/MT Fob Middle east

Lye 50% 400 USD/MT FOB middle east

25 FEB 2023

Quality,analysis and data sheet of caustic flakes

Caustic flakes quality depends on different items and the most import is purity which in our laboratory purity has been measured as ±99% in several times from different batch of production. Caustic soda should be free from heavy metal .here is the Geo Chem quality report .

| SPECIFICATION | UNIT | LIMIT | RESULT |

| Purity of sodium hydroxide(NaOh) | %w | Min 99 | 99.5 |

| Carbonate as Na2CO2 | %w | Max 1 | 0.4 |

| Chloride as NaCl | %w | Max 0.06 | 0.05 |

| Sulfate as Na2SO4 | %w | Max 0.01 | 0.0047 |

| Silicate as SiO2 | %w | Max 0.02 | 0.0019 |

| Fe | Mg/Kg | Max 30 | 12 |

| Insoluble in water | %w | Max 0.1 | 0 |

| Aluminum as AL2O3 | Mg/Kg | Max 20 | <20 |

| Heavy metal as pb | Mg/Kg | Max 20 | <20 |

What is caustic soda prill?

Prill Caustic soda are solid small fuse white pearls its colorless also odorless and very hygroscopic. They are very soluble in water and dissolve very rapidly with intense heat in caustic soda; they are readily soluble in methanol and ethanol. Caustic soda prills and caustic soda solutions are very corrosive to many materials and must be handle with great care.

Our caustic soda prills Formulate using high quality components and advance technologies. They are using in various applications due to their purity, long shelf life and precise composition. They can be easily dissolved in water to save dissolution time. They ensure highest purity of prills and thus high yield/productivity. In addition, QCD has advance instrumentation to perform special tests upon request.

Caustic soda pearls advantages

Pearl caustic soda is a high purity solid anhydrous sodium hydroxide in the form of micro spherical particles (prils, pearls). This microspherical solid has several advantages over flakes or other forms:

- Uniform and optimum size to facilitate good mixing in dry blends with excellent flow properties.

- Its are hard and break resistant. They don’t break down easily into irritating dust and therefore have lower moisture absorption, which reduces the risk of clumping and reduces dust exposure to people handling the product.

- dissolve faster and require less time to stir.

- Being a denser product than flakes, less space is require for the same weight, optimizing the use of storage space and minimizing transportation costs

- Ultra high purity Free flowing, milky white granules

- excellent flow properties

- low tendency to stick together

- excellent air transport properties

- high abrasion resistance

- minimal dust formation

- well suited for transport in road tankers, containers and big bags

very good storability in silos precise dosage - rapidly soluble in water, methanol and ethanol

Which industry use prill and pearls caustic soda

Pearl Caustic soda and Caustic Soda prills are use in many different applications, most notably as a base material in the chemical industry, for the production of aluminum, pulp and paper, surfactants such as soaps, detergents and washing powders, and as a catalyst for the production of biodiesel. Other applications include detergents and disinfectants, the production of pulp and the refining of rayon fibers, the cleaning of metal and wood, the regeneration of ion exchange resins, the production of food and beverages, and the treatment of drinking water, industrial water, wastewater and exhaust air cleaning, Neutralization of acids Aluminum metal Dyes and pharmaceuticals Petroleum products, Vegetable oil processing Pulp and paper ,Cellulose wool Rubber chemicals Sodium salts.

Storage and packing of caustic prill

Our caustic soda pearls must be stored in steel drum or other well-sealed packaging, thickness of packaging must be more than 0.5 mm, compression resistance of packaging must more than 0.5Pa. All packaging must be printed “Corrosive” symbol. Keep container tightly close and in a cool, well-ventilate area.Never add water to this product. In case of insufficient ventilation, wear suitable respiratory equipment.Keep away from incompatibles such as oxidizers, reducing agents, metals, acids, alkalis, moisture. Incase of burning, use water, sand or fire extinguisher to put out fire, however, please pay attention to the corrosive liquid when caustic soda pearls are solv in water.

Physical and chemical properties of pearls caustic soda

| PARAMETER | SPECIFICATION |

| Form | Microspheres: 0.50 – 2.00 mm dia. |

| Appearance | Deliquescent solid |

| Colour | White |

| Odour | None |

| PARAMETER | SPECIFICATION |

| Content in NaOH | 99.0 % (minimum) |

| NaCl | 0.046 % wt (max) |

| Na2CO3 | 0.94 % (max) |

| Na2SO4 | 0.038 % (max) |

| Fe | 5 ppm (wt) (max) |

| Ni pick-up | 3 ppm (wt) (max) |

What is liquid caustic soda lye ?

Liquid caustic soda lye is normally produce by the electrolysis of a sodium chloride (NaCl) solution. Basekim manufactures caustic soda using either membrane or diaphragm electrolytic cells also we dont not use mercury base electrolytic cells to produce caustic soda. The co-products form from the electrolytic production of caustic soda are chlorine and hydrogen.

Liquid caustic soda lye is simply an alkaline liquid caustic soda solution which is An inorganic industrial chemical with wide range of applications It’s a typical alkaline substance made by electrolyzing brine. It is using in wide range of applications even more liquid caustic soda is highly caustic base and alkali therefore can break down proteins at ordinary ambient temperatures and cause severe chemical l burns.

Liquid caustic soda is available as a 50% and 30% solution in two main grades which is different in producing method membrane grade and diaphragm grade , its good to know that Sodium chloride is a raw material and in production method whatever remain show the producing method which is use Membrane grade caustic soda will have less than 100 ppm of the sodium chloride remaining in the product. Diaphragm grade material will have less than 1.1% sodium chloride. Several other differences can be seen in the products when the specification sheets are compared.

Caustic Soda 50% Membrane grade

| Total Alkalinity as Na2O (wt. %) Hydroxide Alkalinity as NaOH (wt. %) Sodium Carbonate as Na2CO3 (wt. %) Sodium Chloride as NaCl (ppm by wt.) Sodium Chlorate as NaClO3 (ppm by wt.) Sodium Sulfate as Na2SO4 (ppm by wt.) Iron as Fe (ppm by wt.) Copper as Cu (ppm by wt.) Nickel as Ni (ppm by wt.) | 39.50 51.00 0.05 100 10.0 25 3.0 0.30 0.50 |

Caustic Soda 50% Diaphragm grade

| Total Alkalinity as Na2O (wt. %) Hydroxide Alkalinity as NaOH (wt. %) Sodium Carbonate as Na2CO3 (wt. %) Sodium Chloride as NaCl (wt. %) Sodium Chlorate as NaClO3 (wt. %) Sodium Sulfate as Na2SO4 (wt. %) Iron as Fe (ppm by wt.) Copper as Cu (ppm by wt.) Nickel as Ni (ppm by wt.) | 39.60 51.00 0.20 1.10 0.30 0.075 9.0 0.30 3.00 |

Physical property of Lye soda

Color: Colorless to slightly color

Physical State: Liquid

Appearance: Clear to opaque

Odor: Odorless

Caustic soda Liquid have different names

- Trade Name: Caustic Soda Diaphragm Grade 7%, 10%, 15%, 18%, 18.5%, 20%, 25%, 30%,

- 35%, 40%, 50%, Caustic Soda Membrane 6%, 7%, 18%, 20%, 25%, 30%, 48%,50%, 50% Caustic Soda Membrane OS, 50% Caustic Soda Diaphragm OS,Membrane Blend, Membrane Cell Liquor, Diaphragm Cell Liquor, Caustic Soda Food Grade

- Synonyms: Sodium hydroxide solution, Liquid Caustic, Lye Solution, Caustic, Lye,Soda Lye,Secondary Caustic Soda Liquids

- Chemical Family: Alkali Metal Hydroxide Solutions

How Caustic liquid transport?

Caustic soda liquid is ship via pipelines, tank trucks, railcars, barges , container and ships. Terminals are use to maintain stocks of our caustic soda in many principal cities. Distributor stocks are also available in these and many other cities and form a network of supply for the end user’s convenience.

How to neutralise caustic soda

Carefully add the acid solution to the caustic soda solution while stirring continuously. The acid should be added slowly to avoid rapid heat generation or excessive foaming.

Packing of caustic soda liquid

lye can be packed in several ways furthermore it can be bulk in iso tank or tanker normally manufacture which has bulk storage area use tanker its more cost effective however if storage is not available we can pack it in IBC or Drum which IBC is more cost effective .

- Iso tank , loading up to 22 Ton

- Tanker , according to road limits can load 22 Ton

- IBC 1.5 Ton

- Drum 200 kgs

Differences of Iran Turkey China India and Dubai UAE caustic soda

Each country has its own production capacity for caustic soda, which can vary depending on factors such as domestic demand, raw material availability, and manufacturing capabilities. China, for example, is known for its large-scale production and export of caustic soda, while other countries may have varying production capacities.

Raw Material Sources

The raw materials use in caustic soda production are primarily sodium chloride (salt) and water. The availability and quality of these raw materials can differ between countries. Some countries may have abundant salt reserves or access to natural brine sources, while others may rely on imported salt or different methods of extraction.

Manufacturing Processes

While the fundamental process of caustic soda production, which involves electrolysis of salt brine, remains the same, variations in manufacturing equipment, technologies, and process optimization can exist. These differences can affect factors such as energy efficiency, product purity, and overall production costs.

Product Specifications

Caustic soda typically has specific purity and concentration requirements depending on its intend application. While the general standard for caustic soda purity is typically high (e.g., 99% or higher), there may be variations in impurity levels, concentration, and physical form (solid, liquid, or flakes) base on regional market demands and industrial requirements.

Packaging and Transportation

Packaging standards and transportation practices may differ between countries. The packaging options for caustic soda can include bulk shipments, drums, bags, or intermediate bulk containers (IBCs). Local regulations and logistics capabilities can influence the packaging and transportation methods adopted within each country.

Pricing and Market Competitiveness

Caustic soda prices can vary due to factors such as production costs, transportation expenses, market demand, and currency fluctuations. Each country may have its own cost structure, pricing dynamics, and competitiveness in the global market.

Regulatory Standards and Certifications

Each country may have its own regulatory standards, safety regulations, and certifications related to caustic soda production, handling, and usage. Compliance with these standards can impact the acceptance and use of caustic soda in different markets.

Caustic soda liquid Properties

| Analysis | Unit | Specification |

| Apperance | – | Clear,Liquid |

| Density | g/ml | 1,51±0,010 |

Chemical Properties

| Analysis | Unit | Specification |

| Total Alkalinity | % | 50,00 Max. |

| Sodium Chloride | ppm | 100 Max. |

| Sodium Chlorate | ppm | 40 Max. |

| Sodium Carbonate | g/kg | 1 Max. |

| Heavy Metal | ppm | 10 Max. |

| Iron | ppm | 5 Max. |

Specification of caustic soda

Specification of caustic soda

MSDS of caustic soda

MSDS of caustic soda

Contact Info

Turkey office:No.6 of Fahrettin Pasa Sokak , Galip Erdem steet, Ilkbahar Mah. Turan Gunes Ave. Çankaya Ankara

Phone: 00903125147055

Dubai office: 3509 of the Burligton tower, business bay, dubai-uae

Phone:0097142369830

E-Mail: [email protected]